Battery Electrode Inspection . improved inspection capabilities are needed to help drive down cost, increase energy densities, and improve overall safety and reliability. a robust online surface inspection system capable of detecting and classifying defects in battery electrodes efficiently and accurately. ametek surface vision delivers trusted highly accurate solutions for battery electrode coating processes, maintaining line speeds and rapidly detecting defects. Coated electrode foils for both cathodes and anodes. • we develop correction algorithms to. using the inspection and monitoring solution provided by ametek surface vision, battery cell manufacturers can be assured of. Unlike traditional techniques, which can be costly, manual and error. our solution represents a significant advance in battery electrode inspection.

from www.alliedvision.com

using the inspection and monitoring solution provided by ametek surface vision, battery cell manufacturers can be assured of. • we develop correction algorithms to. our solution represents a significant advance in battery electrode inspection. Unlike traditional techniques, which can be costly, manual and error. a robust online surface inspection system capable of detecting and classifying defects in battery electrodes efficiently and accurately. ametek surface vision delivers trusted highly accurate solutions for battery electrode coating processes, maintaining line speeds and rapidly detecting defects. improved inspection capabilities are needed to help drive down cost, increase energy densities, and improve overall safety and reliability. Coated electrode foils for both cathodes and anodes.

Visual battery inspection Allied Vision

Battery Electrode Inspection ametek surface vision delivers trusted highly accurate solutions for battery electrode coating processes, maintaining line speeds and rapidly detecting defects. a robust online surface inspection system capable of detecting and classifying defects in battery electrodes efficiently and accurately. using the inspection and monitoring solution provided by ametek surface vision, battery cell manufacturers can be assured of. our solution represents a significant advance in battery electrode inspection. improved inspection capabilities are needed to help drive down cost, increase energy densities, and improve overall safety and reliability. Coated electrode foils for both cathodes and anodes. • we develop correction algorithms to. Unlike traditional techniques, which can be costly, manual and error. ametek surface vision delivers trusted highly accurate solutions for battery electrode coating processes, maintaining line speeds and rapidly detecting defects.

From www.youtube.com

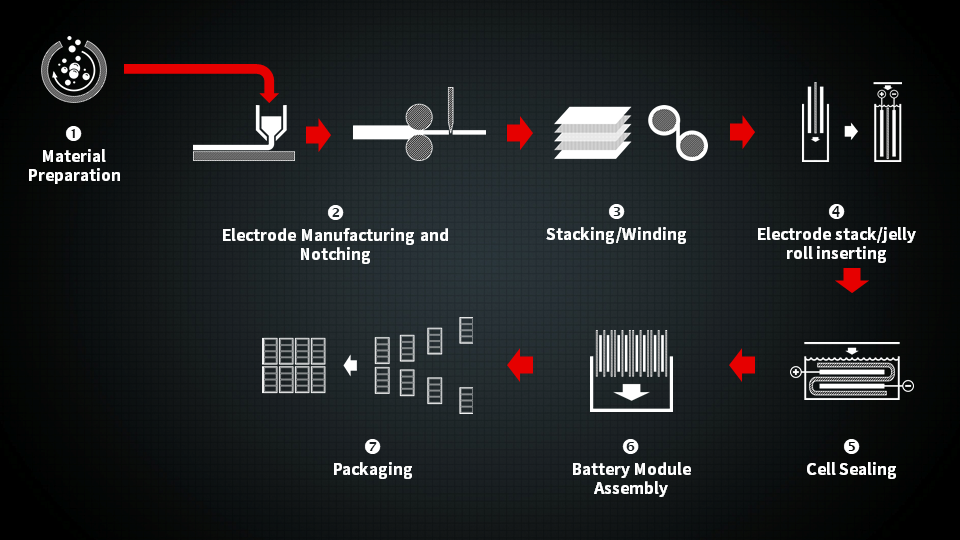

EV Battery Assembly (Step 0) Battery Cell Components Quality Inspection Battery Electrode Inspection Coated electrode foils for both cathodes and anodes. improved inspection capabilities are needed to help drive down cost, increase energy densities, and improve overall safety and reliability. using the inspection and monitoring solution provided by ametek surface vision, battery cell manufacturers can be assured of. • we develop correction algorithms to. Unlike traditional techniques, which can be costly,. Battery Electrode Inspection.

From www.alliedvision.com

Visual battery inspection Allied Vision Battery Electrode Inspection a robust online surface inspection system capable of detecting and classifying defects in battery electrodes efficiently and accurately. • we develop correction algorithms to. using the inspection and monitoring solution provided by ametek surface vision, battery cell manufacturers can be assured of. our solution represents a significant advance in battery electrode inspection. Unlike traditional techniques, which can. Battery Electrode Inspection.

From esst.cip.com.cn

Defects detection and recognition of lithium battery electrode plate Battery Electrode Inspection improved inspection capabilities are needed to help drive down cost, increase energy densities, and improve overall safety and reliability. Unlike traditional techniques, which can be costly, manual and error. our solution represents a significant advance in battery electrode inspection. ametek surface vision delivers trusted highly accurate solutions for battery electrode coating processes, maintaining line speeds and rapidly. Battery Electrode Inspection.

From tmaxcn.en.made-in-china.com

CCD Tester for Battery Electrode Positive and Negative Detection Battery Electrode Inspection a robust online surface inspection system capable of detecting and classifying defects in battery electrodes efficiently and accurately. • we develop correction algorithms to. improved inspection capabilities are needed to help drive down cost, increase energy densities, and improve overall safety and reliability. using the inspection and monitoring solution provided by ametek surface vision, battery cell manufacturers. Battery Electrode Inspection.

From szpaifeite.en.made-in-china.com

Automatic Aluminium Battery Electrode Inspection Machine China Battery Electrode Inspection using the inspection and monitoring solution provided by ametek surface vision, battery cell manufacturers can be assured of. improved inspection capabilities are needed to help drive down cost, increase energy densities, and improve overall safety and reliability. our solution represents a significant advance in battery electrode inspection. ametek surface vision delivers trusted highly accurate solutions for. Battery Electrode Inspection.

From www.dc-precision.com

Wholesale Lithiumion Battery Electrode Inspection Equipment Battery Electrode Inspection a robust online surface inspection system capable of detecting and classifying defects in battery electrodes efficiently and accurately. Coated electrode foils for both cathodes and anodes. our solution represents a significant advance in battery electrode inspection. ametek surface vision delivers trusted highly accurate solutions for battery electrode coating processes, maintaining line speeds and rapidly detecting defects. . Battery Electrode Inspection.

From www.qualitymag.com

Hardness Testing of Individual Battery Electrode Particulates Quality Battery Electrode Inspection improved inspection capabilities are needed to help drive down cost, increase energy densities, and improve overall safety and reliability. Coated electrode foils for both cathodes and anodes. a robust online surface inspection system capable of detecting and classifying defects in battery electrodes efficiently and accurately. our solution represents a significant advance in battery electrode inspection. ametek. Battery Electrode Inspection.

From bauaelectric.com

Thermo Fisher’s new inline metrology enables comprehensive inspection Battery Electrode Inspection a robust online surface inspection system capable of detecting and classifying defects in battery electrodes efficiently and accurately. Coated electrode foils for both cathodes and anodes. Unlike traditional techniques, which can be costly, manual and error. using the inspection and monitoring solution provided by ametek surface vision, battery cell manufacturers can be assured of. our solution represents. Battery Electrode Inspection.

From www.ameteksurfacevision.com

Electrode Inspection Batteries AMETEK Surface Vision Battery Electrode Inspection • we develop correction algorithms to. improved inspection capabilities are needed to help drive down cost, increase energy densities, and improve overall safety and reliability. ametek surface vision delivers trusted highly accurate solutions for battery electrode coating processes, maintaining line speeds and rapidly detecting defects. using the inspection and monitoring solution provided by ametek surface vision, battery. Battery Electrode Inspection.

From www.mdpi.com

Energies Free FullText Analysis of ManufacturingInduced Defects Battery Electrode Inspection a robust online surface inspection system capable of detecting and classifying defects in battery electrodes efficiently and accurately. our solution represents a significant advance in battery electrode inspection. Coated electrode foils for both cathodes and anodes. Unlike traditional techniques, which can be costly, manual and error. using the inspection and monitoring solution provided by ametek surface vision,. Battery Electrode Inspection.

From www.mdpi.com

Batteries Free FullText Coating Defects of LithiumIon Battery Battery Electrode Inspection our solution represents a significant advance in battery electrode inspection. using the inspection and monitoring solution provided by ametek surface vision, battery cell manufacturers can be assured of. Unlike traditional techniques, which can be costly, manual and error. a robust online surface inspection system capable of detecting and classifying defects in battery electrodes efficiently and accurately. Coated. Battery Electrode Inspection.

From twslbatterymachine.en.made-in-china.com

Battery CCD Positive Negative Electrode Testing Machine EV Battery Pack Battery Electrode Inspection Unlike traditional techniques, which can be costly, manual and error. a robust online surface inspection system capable of detecting and classifying defects in battery electrodes efficiently and accurately. using the inspection and monitoring solution provided by ametek surface vision, battery cell manufacturers can be assured of. • we develop correction algorithms to. Coated electrode foils for both cathodes. Battery Electrode Inspection.

From www.mdpi.com

Batteries Free FullText Coating Defects of LithiumIon Battery Battery Electrode Inspection Unlike traditional techniques, which can be costly, manual and error. our solution represents a significant advance in battery electrode inspection. • we develop correction algorithms to. ametek surface vision delivers trusted highly accurate solutions for battery electrode coating processes, maintaining line speeds and rapidly detecting defects. a robust online surface inspection system capable of detecting and classifying. Battery Electrode Inspection.

From www.tmaxcn.com

CCD Visual Inspection Equipment For Positive And Negative Battery Battery Electrode Inspection improved inspection capabilities are needed to help drive down cost, increase energy densities, and improve overall safety and reliability. using the inspection and monitoring solution provided by ametek surface vision, battery cell manufacturers can be assured of. our solution represents a significant advance in battery electrode inspection. Coated electrode foils for both cathodes and anodes. Unlike traditional. Battery Electrode Inspection.

From www.hitachi.com

Inspection and Analysis Solution for Quality Management of Lithiumion Battery Electrode Inspection a robust online surface inspection system capable of detecting and classifying defects in battery electrodes efficiently and accurately. Unlike traditional techniques, which can be costly, manual and error. using the inspection and monitoring solution provided by ametek surface vision, battery cell manufacturers can be assured of. our solution represents a significant advance in battery electrode inspection. . Battery Electrode Inspection.

From www.ameteksurfacevision.com

Separator Inspection Batteries AMETEK Surface Vision Battery Electrode Inspection Coated electrode foils for both cathodes and anodes. • we develop correction algorithms to. our solution represents a significant advance in battery electrode inspection. Unlike traditional techniques, which can be costly, manual and error. a robust online surface inspection system capable of detecting and classifying defects in battery electrodes efficiently and accurately. improved inspection capabilities are needed. Battery Electrode Inspection.

From www.lotsvision.com

light leds (LOTS)Battery electrode tab inspection Battery Electrode Inspection Unlike traditional techniques, which can be costly, manual and error. Coated electrode foils for both cathodes and anodes. • we develop correction algorithms to. using the inspection and monitoring solution provided by ametek surface vision, battery cell manufacturers can be assured of. improved inspection capabilities are needed to help drive down cost, increase energy densities, and improve overall. Battery Electrode Inspection.

From www.mvtec.com

Electrode sheet inspection machine Ayaha Engineering Battery Electrode Inspection ametek surface vision delivers trusted highly accurate solutions for battery electrode coating processes, maintaining line speeds and rapidly detecting defects. Unlike traditional techniques, which can be costly, manual and error. our solution represents a significant advance in battery electrode inspection. using the inspection and monitoring solution provided by ametek surface vision, battery cell manufacturers can be assured. Battery Electrode Inspection.